Industrial catalysts

Industrial catalysts

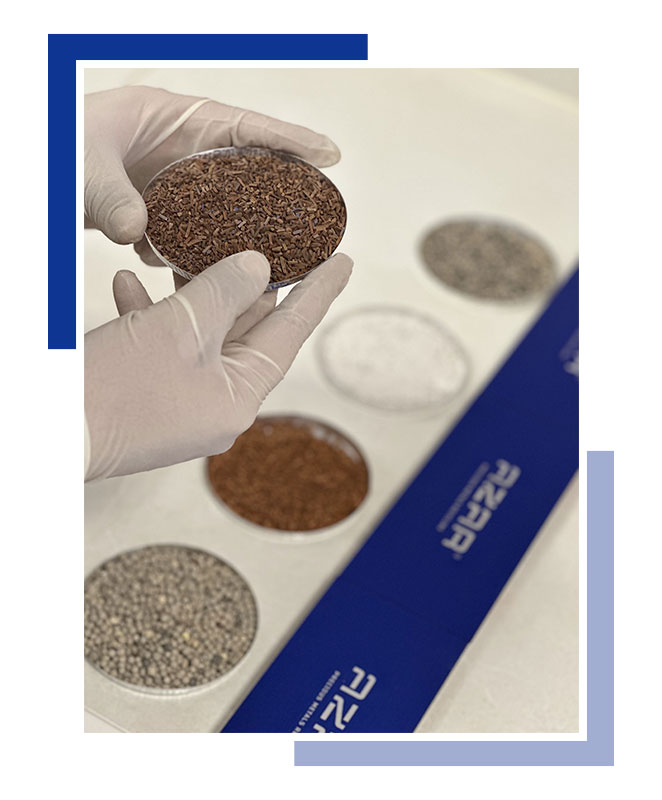

Petrochemical and refinery catalysts containing PGM (Platinum Group Metals) are used in the oil and gas industry to facilitate various chemical reactions involved in the production of fuels, chemicals, and other petrochemical products. These catalysts are typically used in processes such as catalytic cracking, hydrocracking, reforming, isomerization, and hydrotreating. Each of these processes involves different reactions and requirements, but they all rely on PGM catalysts to enhance the efficiency and selectivity of the reactions. PGM catalysts, including platinum, palladium, and rhodium, are chosen for their unique properties that make them suitable for these demanding applications. These properties include high catalytic activity, resistance to high temperatures and corrosive environments, and stability over extended periods of use.

In catalytic cracking, for example, PGM catalysts are used to break down heavy hydrocarbon molecules into lighter ones by breaking carbon bonds. This process is essential for the production of gasoline and other lighter fractions from crude oil.

Hydrocracking is another important process that uses PGM catalysts. It involves the breaking of hydrocarbon molecules using hydrogen gas under high pressure and temperature.This process helps to remove impurities and convert heavy fractions into lighter, more valuable products. Reforming is a process that converts low octane naphtha into high octane gasoline by rearranging the molecular structure of hydrocarbons. PGM catalysts play a crucial role in promoting the desired reactions and improving the quality of the final product. Isomerization is a process used to convert straight chain hydrocarbons into branched chain isomers, which have higher octane ratings. PGM catalysts are used to facilitate this reaction and increase the yield of high octane gasoline.

Hydrotreating is a process used to remove sulfur, nitrogen, and other impurities from crude oil and petroleum products.

PGM catalysts are employed to promote the reactions that convert these impurities into less harmful substances, improving the quality and environmental impact of the final products.

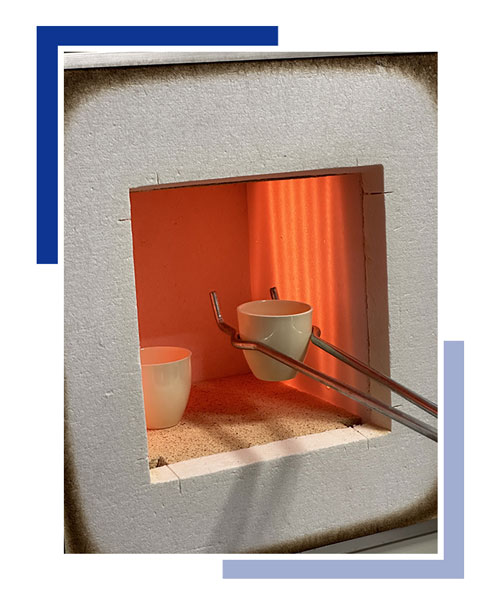

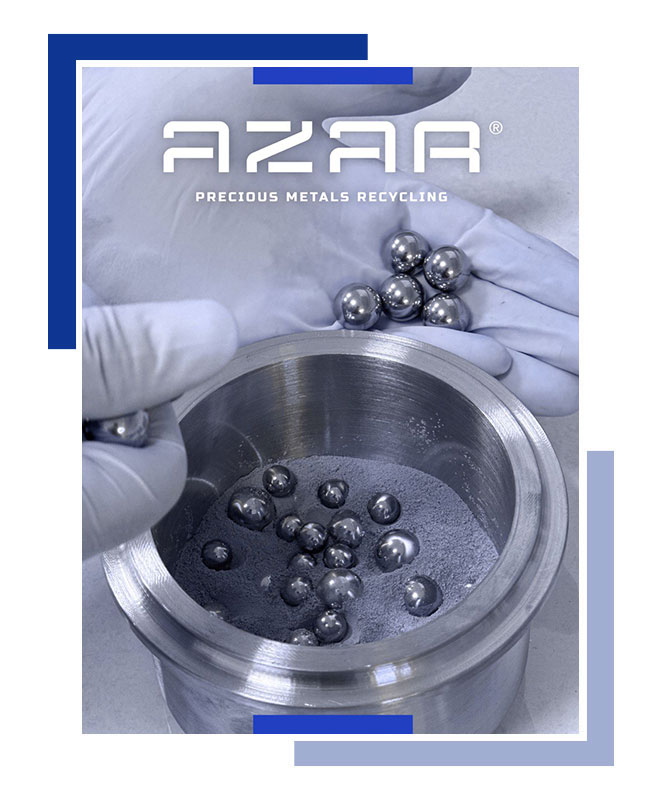

Overall, PGM catalysts are essential in petrochemical and refinery processes as they enhance the efficiency, selectivity, and environmental performance of these operations. Their unique properties and ability to facilitate various chemical reactions make them indispensable in the production of fuels and other petrochemical products. At AZAR we specialize in the transformation of precious metals into new and valuable resources. Our focus lies on the recycling of automotive and industrial catalysts, which play a crucial role in various industrial processes. We are dedicated to purchasing catalysts that have reached the end of their lifecycle, ensuring that these valuable materials are not wasted. By doing so, we contribute to the conservation of natural resources and the production of new metals. Our professional team is equipped with the expertise and technology necessary to process precious metals from spent catalysts, maximizing their value and potential for reuse.

By choosing AZAR, you can be confident that your endof life catalysts will be handled with care and efficiency,while also contributing to a more sustainable and circular economy.